Eldsneyti

Biodiesel is made from organic waste, such as frying oil, fish waste, and slaughter waste. Biodiesel can also be extracted from oil-rich plants, such as rapeseed. Both biodiesels can be used as an additive to ordinary diesel oil. The mixture can be used directly as fuel on conventional diesel engines without changing the machines.

In Iceland, biodiesel oil is produced from used frying oil and fat waste at Orkey EHF., located in Akureyri.

Orkey EHF., Efnamóttakan, and other waste collectors have worked hard to build a system for collecting used frying oil for Orkey’s biodiesel production.

Good experience has now been gained in the collection and reception of frying oil at both restaurants and the public. In Akureyri, Terra and Gámaþjónustan collect used frying oil in restaurants and canteens. However, the public can collect and return oil to local stations through the project The Green Funnel - Energy from the kitchen. The project is collaborative between Norðurorka, Orkusetur, Vistorka, and Terra. The Green Funnel can be accessed at Norðurorka's customer service center or the City Hall's service lobby.

This arrangement also prevents the oil from ending up in the town's sewerage systems, with associated problems and costs.

Most of Orkey’s biodiesel is sold as a combustion catalyst on fishing vessels instead of imported substances. Then 1.5% biodiesel is mixed into marine oil. The mixing occurs at Olíudreifing, so the mixture comes ready for the dock. The properties of biodiesel result in perfect combustion of the oil and less contamination.

Biodiesel has also been used as a bitumen additive in road paving, as a cleaning agent in fuel systems, and as a fuel for larger diesel vehicles, e.g., buses, garbage trucks, and other trucks.

By using biofuels produced from waste in Iceland, CO2 emissions can be reduced and the need for imported fuels reduced.

The utilization of waste in this way also reduces the amount of waste that would otherwise have been landfilled.

Methane is a compound of carbon and hydrogen with the chemical formula CH4. Methane is a gas odorless and lighter than air and evaporates quickly if it comes into contact with the atmosphere.

Methane is the primary source of biogas and has therefore been used to produce methane as a fuel for cars.

Landfill gas released directly into the atmosphere is about 25 times more harmful than CO2 formed during the combustion of methane, e.g., in a car. Therefore, the utilization of the methane, which would otherwise flow directly into the atmosphere, is of great benefit to the environment and economically viable in that for every Nm3 (standard cubic meters) of methane burned in the engine, liters of imported fossil fuels are saved.

Norðurorka hf. has since 2014 produced methane gas from the old landfills in Glerárdalur above Akureyri. The landfill was utilized from 1972 to 2009, and they are unsorted piles, i.e., everything was mixed. Landfill gas is formed over time, under anaerobic conditions, where the methane content is about 57%.

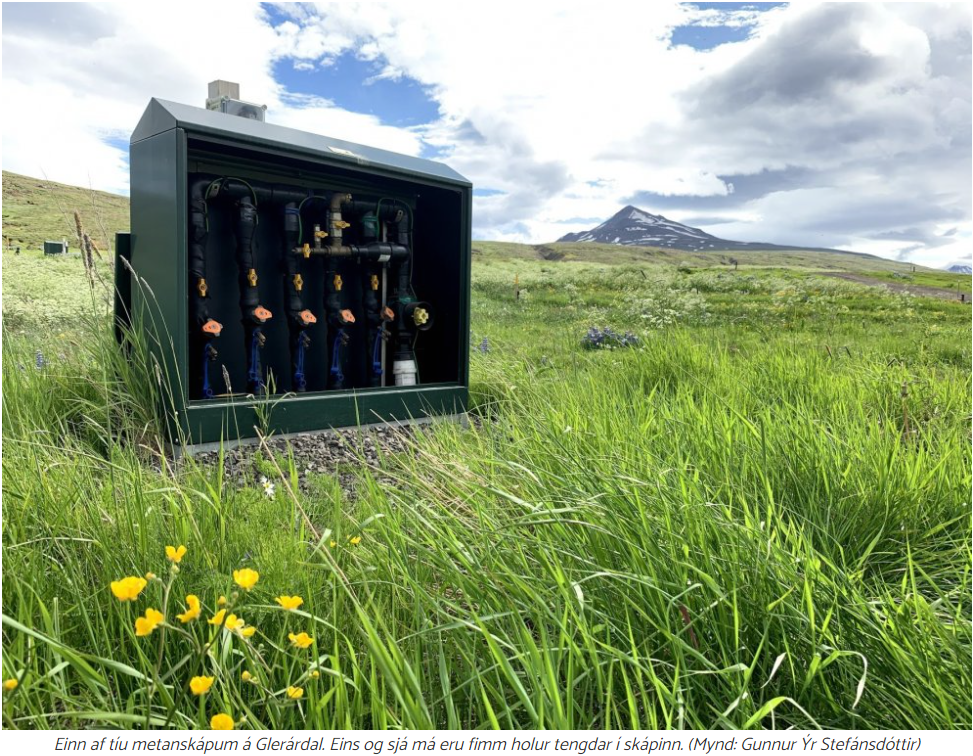

The project involves collecting biogas from 45 boreholes that have been drilled in the area. Five holes are connected in one collection cabinet, where each hole can be measured and adjusted separately. The landfill gas is then purified in a so-called water treatment plant, forming methane gas. From the treatment plant, the methane is led to a compressor station which compresses the methane gas to a pressure of 230 bar on the methane storage, at the same time as the delivery of the vehicle. OLÍS is responsible for marketing and retailing methane that Norðurorka produces.

Methanol is a fuel that can be used on custom-built cars or as an admixture in petrol, but methanol is also an essential raw material in biodiesel production.

In Iceland, the company Carbon Recycling International (CRI) produces methanol by utilizing carbon dioxide emissions from HS Orka's geothermal power plant in Svartsengi, minimizing emissions from the power plant.

Methanol is produced as a renewable fuel from hydrogen, produced by electrolysis of water and carbon dioxide released using geothermal energy. It can therefore be said that methanol is used as a storage medium for hydrogen. The advantages of methanol over pure hydrogen are mainly related to storage. The methanol is, e.g., liquid but not gas and therefore does not need to be stored in unique pressure vessels. Like hydrogen, methanol can be used as fuel in engines and vehicles. In addition, methanol can be blended into gasoline, just like ethanol. Methanol produced in Iceland is mainly exported.

The primary purpose of this production is to close the carbon cycle by capturing carbon dioxide from a plant's emissions and placing it in a cycle system.

Bioethanol is produced from biomass; it can be made from simple biomass such as cereals or sugar cane. However, such production is very controversial as these raw materials are also used as food and their utilization in bioethanol production, therefore, leads to an increase in food prices.

Therefore, other options have been considered where complex biomass is used to produce bioethanol. These include agricultural products such as grass, hemp and straw, wastepaper, and even other waste. In Sweden, bioethanol has been made from wood residues generated by Sweden's sustainable wood industry.

One of the main advantages of bioethanol over other environmentally friendly fuels such as methane and hydrogen is that bioethanol is in liquid form. Therefore, it can be distributed to consumers just like gasoline.

Hydrogen is a promising green option for fuel production.

Hydrogen is a gas that is abundant in the earth, but a large part of it is bound in the compound H2O, which is water. To obtain pure hydrogen, water is split into hydrogen and oxygen by passing an electric current through the water, as can be seen in the following equation:

2H2O (l) → 2H2 (g) + O2 (g)

On the other hand, Electrolysis is an energy-intensive process and requires a lot of electricity. At the Hellisheiði power plant's production facilities, the nighttime has been used for hydrogen production because there is plenty of excess electricity. To make the best use of the resources, it is essential that it is possible to utilize all the electricity that is produced by being able to store the excess energy that is generated during production. Most of us are familiar with storing electricity in the form of batteries. Hydrogen has the same properties, which can store electricity. At the end of the production process, the hydrogen is collected and stored in pressure vessels to be used later. Hydrogen and batteries are, in fact, different methods of storing electricity, each with its advantages and disadvantages.

Ammonia (NH3) is chemically quite different from other fuel options as there is no carbon in the compound. Its combustion, therefore, releases no CO2 into the atmosphere.

Ammonia itself, however, is not a safe substance. It is a toxic and corrosive gas and can be deadly if it enters the atmosphere at 0.5% saturation.

On the other hand, ammonia has many significant advantages in fuel potential, especially when it comes to hydrogen storage options. Hydrogen (H2) is also a gas and to store it in liquid form requires either -260 ° C frost or high pressure. Since ammonia can be converted to hydrogen, ammonia is a storage option for hydrogen. It would be easier to transport it between countries because much less cold is required to store ammonia in liquid form, or -33 ° C and standard pressure. The temperature and pressure are therefore much more manageable, in addition to which the density of hydrogen in ammonia is considerably higher than the density of hydrogen gas under pressure.

The technology for using ammonia as a fuel is in the experimental stage, but where ammonia is one of the most common substances in the chemical industry, e.g., in the production of fertilizers, the infrastructure to produce ammonia, and the technology for transporting and storing ammonia are already in place around the world.

Ammonia is, therefore, an exciting option when it comes to clean energy sources. No carbon is released during combustion, which makes this possibility very sought after. Hydrogen and renewable electricity are the only advantages on par with ammonia.